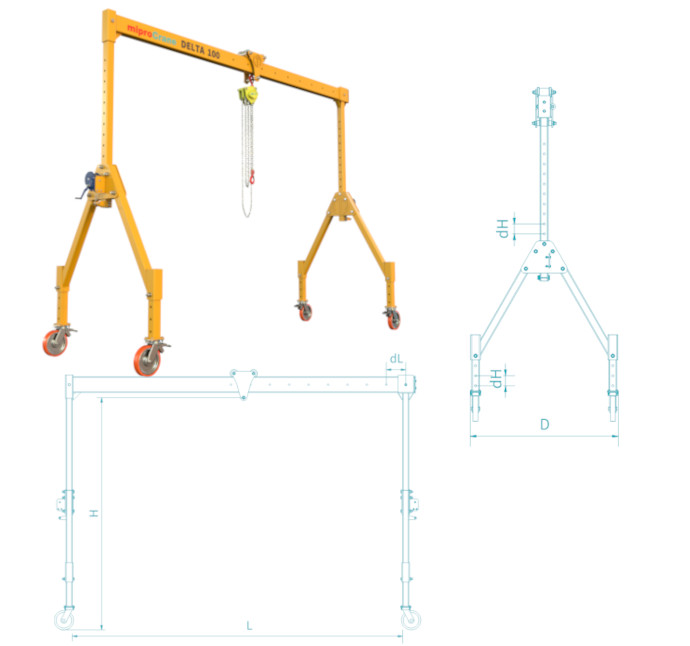

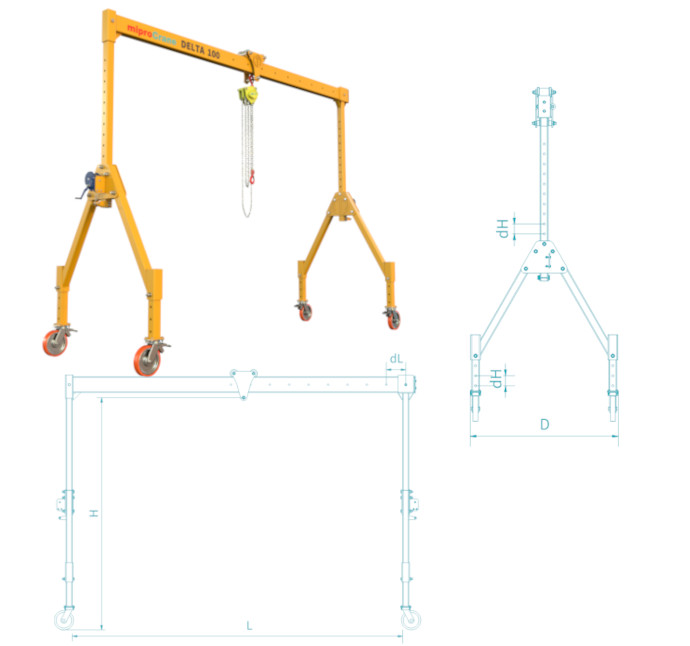

Mobile gantry crane with height adjustment DELTA 100

- The gantry crane is designed for lifting, lowering and moving loads located in its working space, which is determined by the length of the bearing beam. The load capacity of the gantry winch is determined for the entire range of work of the bearing beam

- The gantry crane is designed to lift, lower and move loads located in its working space, which is determined by the length of the supporting beam. The load capacity of the gantry winch is specified for the entire operating range of the supporting beam

- The gantry crane can be folded or disassembled into simple components for easy servicing, transportation or storage

- Short installation time, possibility of relocation

- Precision, speed, safety and comfort of operators

- Low noise level during use

- Trolley: manual

- Chain hoist: manual

Electric hoist gantry cranes are equipped with:

- an electric box with a receiving socket

- spiral cable route

- optional additional electrical socket at the hoist, enabling powering suspended devices, e.g. vacuum grippers with an electric pump

- Chassis - four swivel castors with brakes

Gantry crane DELTA 100 allows for adjustment:

- the height of the support beam

- the height of the driving supports

- the length of the working part of the support beam.

The gantry crane can be folded or disassembled into simple components, making it easier to service, transport or store.

Wheelsets:

- Four swivel castors brake

- SK Travel direction lock (every 90°) (option)

- SA Underrun protection (option)

- Separate height adjustment of each support driving

Adjusting the height and length of the support beam:

- Lifting/lowering by crank

- Locking with screws

- Adjustable height of driving supports

- Adjustable length of the supporting beam

|

Code

|

WLL

[kg]

|

H

[mm]

|

L

[mm] |

D

[mm] |

dH

[mm] |

dL

[mm] |

Mass

[kg] |

| DELTA 100 |

1 500 |

1702- 3002 |

1600-3850 |

1488 |

100 |

250 |

350 |

Recommended equipment. Optional:

- hoist ESW

- hoist VX

- hoist SBE

|

ESW

WLL: up to 1500 kg

|

VX

WLL: up to 1250 kg

|

SBE

WLL: up to 1500 kg

|

|

|  |

|

|---|

|

SHOW

| |

SHOW

|

|---|

|

Electrical equipment

(for cranes with electric hoist):

- EB1 three-phase electrical socket with rotary switch

- EB2 three-phase electrical socket with main rotary disconnector and overcurrent protection, voltage monitoring relay and activation button, mounted on an electrical box with an 8-module DIN rail for mounting modular devices of the TH35 system

- Spiral cable route

- SG additional electrical socket at the hoist, enabling power supply of suspended devices, e.g. vacuum grippers with an electric pump (option)

Control:

|

Cassette control ST

- The cassette is suspended under the hoist or on a separate cable line

- For hoists with an electric trolley and cranes with an electric drive for rotation of the cassette arm with 4, 6 or 8 buttons

|

Cassette control SE

- The cassette is suspended under the hoist or on a separate cable line

- The ergonomic shape allows for safe control with one hand

|

|

|

Control with a manipulator SM

- Only VERLINDE hoists Control buttons and manipulator integrated with the load hook

- It allows for safe control and simultaneous precise

two-handed maneuvering of the hook and load

|

Control cylindrical SC

- Only KITO EDC hoists

- Steering cylinder integrated with the load hook

- It allows for safe control with one hand while maneuvering the load hook

- The handle housing contains a main and alarm switch, potentiometers determining the upper and lower limits of the lifting speed, a speed range switch and diodes indicating the device status

|

|

|

|

|

![]()

Product Comments

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent