Pillar-mounted slewing jib crane BETA 500

- Slewing range: 270°

- Rotation: manual

- Chain hoist: electric or manual

- Trolley: manual

- Control from the attached cassette to hoist or separately

Outreach

[m] |

1 |

2 |

3 |

4 |

5 |

6 |

WLL

[kg] |

63 |

* |

* |

* |

* |

* |

* |

| 80 |

* |

* |

* |

* |

* |

* |

| 125 |

* |

* |

* |

* |

* |

* |

| 250 |

* |

* |

* |

* |

* |

* |

| 500 |

* |

* |

* |

* |

* |

* |

| 1000 |

* |

* |

* |

* |

|

|

Arm beam profile:

- Cold-bent supporting channel (system)

- The carriages move inside the profile

- Trolley and cable trolleys compatible with popular monorail suspended track systems

Recommended equipment. Optional:

- hoist ESW with hand trolley WS

- hoist EVW with hand trolley WS

- hoist VX with hand trolley WS

- hoist SBE with hand trolley WS

- Balanser

ESW-WS

WLL: up to 1000 kg |

EVW-WS

WLL: up to 500 kg |

VX-WS

WLL: up to 1000 kg |

SBE-WS

WLL: up to 1000 kg

|

Balanser

WLL: up to 180 kg

|

|

|

|  |

|

|---|

|

|

Control:

|

Cassette control ST

- The cassette is suspended under the hoist or on a separate cable line

- For hoists with an electric trolley and cranes with an electric drive for rotation of the cassette arm with 4, 6 or 8 buttons

|

Cassette control SE

- The cassette is suspended under the hoist or on a separate cable line

- The ergonomic shape allows for safe control with one hand

|

|

|

Control with a manipulator SM

- Only VERLINDE hoists Control buttons and manipulator integrated with the load hook

- It allows for safe control and simultaneous precise

two-handed maneuvering of the hook and load

|

Control cylindrical SC

- Only KITO EDC hoists

- Steering cylinder integrated with the load hook

- It allows for safe control with one hand while maneuvering the load hook

- The handle housing contains a main and alarm switch, potentiometers determining the upper and lower limits of the lifting speed, a speed range switch and diodes indicating the device status

|

|

|

|

Arm rotation drive:

NB manual drive

- Arm rotation caused by manual movement of a load or load chain

Working area limitation:

SO-B Adjustable arm rotation limiter (bumper), mounted on the arm

- Limits the movement of the crane arms in zones dangerous to the operation of the crane, people or nearby devices and installations, or facilitates work by limiting unnecessary arm movements

- The position of the stops is adjusted using screws and mounting holes

Rotation retarder:

SP Arm rotation decelerator (optional)

- It can only be used in the absence of an electric drive for arm rotation

- Prevents sudden or uncontrolled rotation of the arm

- Enables precise positioning of the load

- Standardly installed on all crane joints

- Principle of operation: friction with adjustable pressure force

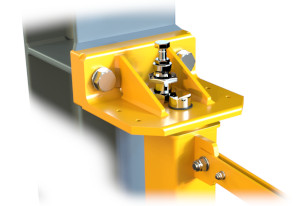

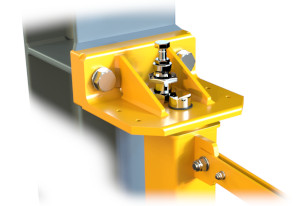

Arm rotation lock:

SB Arm rotation lock (option)

- Allows you to securely lock the arm in the selected position

- Locking using a pin with an eye and a disc with holes at the lower yoke of the arm rotation axis

- The lock can be single-point or multi-point

- By default, the arm is locked at one point in the "straight" position

Cable route:

Single cable route TK05

- Control box suspended under the trolley or hoist

- Integrated power and control cable in the form of a garland on moving objects cable hangers

- Cable trolleys routed in one track with a trolley (moving inside arm profile)

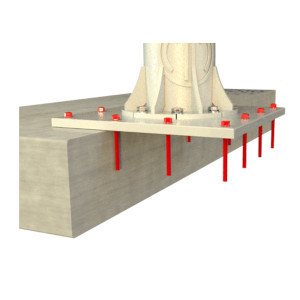

Floor fixing of pillar jib cranes:

Basic recommended methods of foundation of BETA series pillar cranes:

- fixing with anchors on a reinforced foundation

- fastened to the concrete floor through a steel intermediate plate on chemical anchors.

|

|

|

|

|

|

MP Fastening to the concrete floor via steel

intermediate plate on chemical anchors

|

MF Reinforced foundation with anchors

|

![]()

![]()

Product Comments

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent