Pillar-mounted slewing jib crane BETA 100

- Slewing range: 360°

- Rotation: electric or manual

- Chain hoist: electric or manual

- Trolley: electric or manual

- Control from the attached cassette to hoist or separately

- Made of high-strength steel

- Anti-corrosion protection by machine shotblasting and two-layer spray painting

- Support column made of steel pipe. Height and diameter adapted to the user's requirements

- The ribbed foot of the load-bearing column ensures a solid and safe attachment of the crane to the ground. Optionally, an intermediate orifice for installation on the floor using chemical anchors

- The swivel arm of the crane is made of the IPE profile as standard. Adapted to work with a wide range of trolleys and hoists

- A wide range of options for mechanical design, equipment and fastening allows our cranes to be used efficiently in many industrial applications

- Short installation time, possibility of relocation

- Precision, speed, safety and comfort of operators' work

- Low noise level during use

Due to the large variety of possible technical solutions, BETA 100 cranes are made for specific working conditions specified in the order - working area size, load capacity, outreach, method of foundation, work intensity group, etc.

We do not offer "finished" cranes. Each of our products is a separate, specific project, bearing its own number, its own certificate and instruction manual.

Outreach

[m]: |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

WLL

[kg]:

|

125 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 250 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 500 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 1 000 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 1 500 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 2 000 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 2 500 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 3 000 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

| 4 000 |

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

|

| 5 000 |

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

Recommended equipment. Optional:

- hoist ESW with electric trolley EWE

- hoist ESW with hand trolley EWP

- hoist EVW with hand trolley EWP

- hoist VX with hand trolley WP

- hoist VX with electric trolley WE

- hoist SBE with hand trolley POT

|

ESW+EWE

WLL: up to 5000 kg

|

ESW+EWP

WLL: up to 2000 kg

|

EVW+EWP

WLL: up to 500 kg

|

|

|

|  |

|---|

|

|

|

|

|---|

|

VX+WE

WLL: up to 2500 kg

|

VX+WP

WLL: up to 1250 kg

|

SBE+POT

WLL: up to 5000 kg

|

|

|

|

|---|

| | |

|---|

|

Control:

|

Cassette control ST

- The cassette is suspended under the hoist or on a separate cable line

- For hoists with an electric trolley and cranes with an electric drive for rotation of the cassette arm with 4, 6 or 8 buttons

|

Cassette control SE

- The cassette is suspended under the hoist or on a separate cable line

- The ergonomic shape allows for safe control with one hand

|

|

|

Control with a manipulator SM

- Only VERLINDE hoists Control buttons and manipulator integrated with the load hook

- It allows for safe control and simultaneous precise

two-handed maneuvering of the hook and load

|

Radio control SR

- Tele-Radio Panther 2.4 Ghz 16-channel system

- No cable connection between the cassette and the hoist or crane - remote operation possible 8-button cassette + transmitter mounted on a crane

- A wired control unit is included in the set in case of radio failure or operation in EM interference conditions

|

|

|

|

Cable route:

|

TK01 Single

|

TK02 Double

|

The control box is suspended under the trolley

|

The control cassette moves independently of the trolley

|

|

Arm rotation drive:

- NB manual drive

- NG upper drive with gear transmission in the arm rotation axis (option)

- ND electromechanical friction drive with double rollers (option)

Working area limitation:

SO-A fixed arm rotation limiter, screwed to the column during crane assembly (option)

- Limits the movement of crane arms in zones dangerous to the operation of the crane, people or nearby devices and installations

- After analyzing the hazards and working conditions, the limiters are installed "permanently" in a way that prevents quick or accidental disassembly

- Additional fixed stops (bumpers) are mounted at the ends of the working part of the arm, limiting the movement of the trolley along the arm.

Electrical equipment:

- SE steel cover for the main switch on the column

- SG additional electrical socket at the hoist, enabling power supply of suspended devices, e.g. vacuum grippers with an electric pump (option)

Fixing methods:

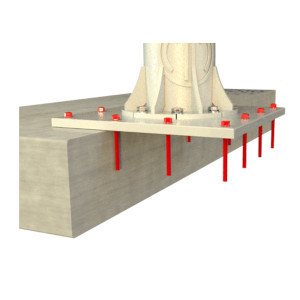

Basic recommended methods of foundation of BETA series pillar cranes:

- fastening with anchors on a reinforced foundation

- fastening to the concrete floor via a steel intermediate plate on chemical anchors.

|

|

|

|

|

|

MP Fixing to the concrete floor via steel intermediate plate on chemical anchors

|

MF Reinforced foundation with anchors

|

![]()

![]()

Product Comments

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent